Technology

Lumentek luminaires meet the highest requirements for outdoor lighting with consideration of 18 key points in the production of quality solar street light

17 key points you must know about quality solar streetlights

1- DON'T JUST LOOK AT THE PARAMETERS ONLY

When investing in quality solar streetlights, it’s imperative not to solely rely on the specifications provided by suppliers. Advertised as having a 100Ah battery, the actual product may contain only 10Ah. Moreover, batteries of the same capacity may vary in available capacity due to different grades. While some suppliers label their products as 60W, others may inflate the figure to 300W for identical solar streetlights.

2- CHEAP & LOW-QUALITY SOLAR LIGHTS = WASTE OF MONEY

While cost-conscious consumers often gravitate towards the cheapest options, affordability doesn’t always translate to cost-effectiveness. The durability and performance of the product are equally critical factors to consider. For example:

- A $300 high-quality solar light with a 10-year lifespan results in an average annual cost of $30.

- Conversely, a $100 poor-quality solar light lasting only one year entails an average annual cost of $100. Additionally, the wasted time and energy costs associated with frequent breakdowns render it an unwise investment.

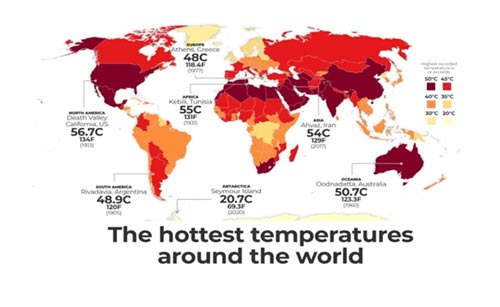

3- LOCAL TEMPERATURE, LATITUDE

- LiFePO4 lithium batteries can withstand charging and discharging environment temperatures of up to 65 degrees Celsius.

- Ternary li-ion lithium batteries, in contrast, tolerate temperatures up to 50 degrees Celsius.

- During summer, solar panels can reach a scorching 90 degrees Celsius.

Hence, in hot regions such as Africa (e.g., Algeria, South Africa, Angola), the Middle East (e.g., Saudi Arabia, Kuwait, Qatar, Oman, UAE), Southeast Asia (e.g., Malaysia, Philippines), and South America (e.g., Chile, Mexico), LiFePO4 lithium batteries are the preferred choice, given the fire risk associated with ternary batteries. It’s essential to ensure optimal lamp heat dissipation performance and avoid direct contact between the solar panel and battery.

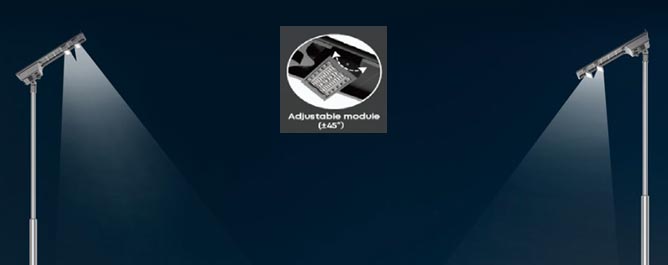

For areas with latitudes exceeding 15 degrees, solar streetlights with adjustable solar panel angles are recommended to accommodate the sun’s inclination angle. Additionally, when installing solar streetlights on both sides of the road, ensure that solar panels face sunlight to maximize efficiency.

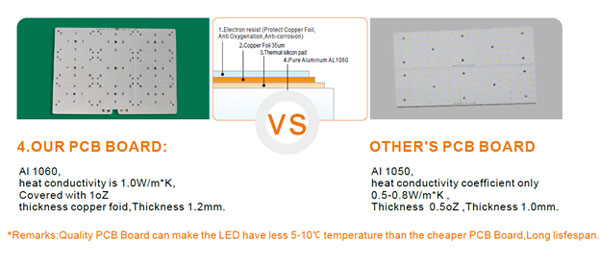

4- Lamp Heat Dissipation Performance

The performance of lamp heat dissipation is critical for LED street lights. A mere 10-degree increase in the PN junction temperature of the LED chip can significantly diminish the lifespan of the semiconductor device. Adequate heat dissipation is essential to ensure the longevity and quality of LED street lights. Unfortunately, some manufacturers cut corners to reduce costs, leading to potential hazards that may not be immediately evident but become apparent over time.

Impact of Temperature on Battery Life

Temperature plays a pivotal role in the calendar life and cycle life of lithium batteries, governed by the Arrhenius equation. As temperature rises, the reaction speed within lithium batteries accelerates.

Research indicates that for every 10°C increase in temperature, the degradation rate of lithium batteries doubles. For instance, a battery cell with 90% remaining capacity yields 300kWh output at 25°C, whereas at 35°C, the output drops to a mere 163kWh. Additionally, a 10°C temperature rise can halve the cycle life of a battery cell.

Impact of Temperature on Battery Life

Temperature plays a pivotal role in the calendar life and cycle life of lithium batteries, governed by the Arrhenius equation. As temperature rises, the reaction speed within lithium batteries accelerates.

Research indicates that for every 10°C increase in temperature, the degradation rate of lithium batteries doubles. For instance, a battery cell with 90% remaining capacity yields 300kWh output at 25°C, whereas at 35°C, the output drops to a mere 163kWh. Additionally, a 10°C temperature rise can halve the cycle life of a battery cell.

Temperature Control for Battery Maintenance

Given the profound impact of temperature on lithium battery performance, it is imperative to avoid prolonged exposure to high temperatures during battery use, especially during high-rate chargedischarge cycles. Effective temperature control is essential to safeguard battery health and longevity.

Considerations for Lamp Heat Dissipation

Given these factors, the lamp’s heat dissipation performance must be carefully considered. Solar panels, when exposed to sunlight, can reach scorching temperatures. To mitigate potential damage, it is crucial to ensure that the solar panel is not positioned adjacent to the battery or the LED light source. Proper positioning is essential to maintain optimal performance and prolong the lifespan of the entire solar streetlight system.

5- FOUR TYPES OF LITHIUM BATTERIES

THE ACTUAL CAPACITY OF THE BATTERY SOME PARAMETER TABLES AH LOOK VERY BIG, BUT ALWAYS CONSIDER WH INSTEAD OF AH. Wh=Ah*V, we can’t just look at the capacity of Ah, but also the voltage. E.g.:

- 90Ah, 3.2V actual battery capacity is 90Ah*3.2V=288Wh.

- 30Ah, 12.8V actual battery capacity is 30Ah*12.8V=384Wh

Available battery capacity

A deep charge and discharge will consume the battery’s capacity, so to protect the battery, the battery power is generally not reduced to the minimum. Different quality batteries have different pre-stored power ratios, for example, Lead-acid batteries must reserve 50% of the power, so the depth of discharge is 50% of the actual capacity.

The ternary battery must have 30% of the power, so the depth of discharge is 70% of the actual capacity LiFePO4 Lithium battery only needs to reserve 1% of power, so the depth of discharge can reach 99% of the actual capacity.

It can be seen that, in order to achieve the same available capacity, the ternary li-ion battery configuration must be higher than that of the LiFePO4 lithium battery.

What is A grade or Class A battery cell?

The battery factory arranges production according to the production capacity and technical capacity of the factory. After a series of battery manufacturing processes, the final product is delivered to the customer; After mass production of battery cells with the same specifications, it is necessary to measure the cells’ rated capacity and internal resistance through a series of testing procedures. If the rated capacity of the cell reaches A predetermined value, the internal resistance is lower than the specified value, and the appearance, performance, and other qualified cells are called Grade A cells. specified value, and the appearance, performance, and other qualified cells are called Grade A cells.

What is a B-grade or Class B battery cell?

Any factory producing products must have a defect rate. Then this defect rate determines the vitality of a factory. There will not be a big gap between the first-line lithium battery and the third-line lithium battery factory in the lithium industry, purely technology, ingredients, etc. Still, the gap between the defect rate is enormous; the first-tier manufacturers can achieve about 2%. In comparison, the second and third-tier manufacturers are likely to achieve 5-10%. It is precisely because of this defect rate that

grade B cell is created. The grade B battery in rated capacity, internal resistance, appearance, or performance, and the Grade A cell has a certain gap.

Class A LiFePO4 Lithium Battery

- 2000 charge and discharge cycles

- 10-15 years lifespan

- Good high-temperature stability

- Depth of discharge up to 99%

Class B LiFePO4 Lithium Battery

- 1200-1500 charge and discharge cycles

- 5-6 years lifespan

- Good high-temperature stability

- Depth of discharge up to 99%

Class C Ternary li-ion lithium battery

- 800 charge and discharge cycles

- 3-4 years lifespan

- Easy to catch fire at high temperature

- Depth of discharge up to 70%

Class D Disassemble lithium battery

- 300 charge and discharge cycles

- Less than one year lifespan

- Unstable

- Capacity decay Fast

6- SOLAR PANEL

The solar panel not only depends on the size but also its conversion efficiency. Generally, the conversion efficiency of polycrystalline silicon solar panels is 16-17%, and the conversion efficiency of monocrystalline silicon solar panels is 15%-24%. The manufacturing cost of monocrystalline solar panels is higher than that of polycrystalline solar panels.

Polycrystalline silicon solar panels:![]()

- Conversion efficiency>16%-17%

- Lifespan of 15 years

- Decay rate after ten years: 80%

- Low-strength tempered glass

Monocrystalline solar panels:

- Conversion efficiency>21-24% Life span 25 years

- Decay rate after 10 years: 10%

- High-strength tempered glass, anti-freezing, anti-sandstorm

Monocrystalline Solar Panels and Cutting-Edge Technologies

Monocrystalline solar panels are continuously evolving with technological advancements. Some of the latest techniques include HJT, Topcon, and PERC, briefly described as follows:

- HJT (Heterojunction with Intrinsic Thin-layer) Technology: HJT combines monocrystalline solar cells with amorphous thin-film cells. This technology offers higher efficiency and lower energy losses at high temperatures. The amorphous thin-film layer structure reduces light reflection and increases absorption.

- Topcon (Tunnel Oxide Passivated Contact) Technology: Topcon uses tunnel oxide layers in contact with silicon to enhance efficiency. This technology reduces recombination losses in the cells, thereby improving overall panel performance. These panels perform better, especially under low light conditions.

- PERC (Passivated Emitter and Rear Cell) Technology: PERC involves adding additional layers on the back of monocrystalline cells to reflect more light. This technology increases the efficiency of the solar cells and reduces energy losses. PERC panels perform exceptionally well under low light and cloudy conditions.

Silicon Heterojunction solar cell (short for “HIT” or “HJT” ) combines technical advantages of crystalline silicon cells and amorphous silicon cells. HJT solar cell has low temperature coefficient, excellent weak-light response, high bi-facial power gain and no LID. It can also made by supper-thinner silicon wafer. These features enable it the most potential and competitive crystalline solar cell.

What are the Technical Advantages of HJT Compared to PERC and TOPCon?

When comparing Heterojunction Technology (HJT), Tunnel Oxide Passivated Contact (TOPCon), and Passivated Emitter Rear Cell (PERC) solar panels across various technical parameters, the following data highlights the advantages of HJT:

- In terms of blfadality, HJT solar panels lead with a 95% efficiency, surpassing TOPCon at 85% and PERC at 70%. This higher biracially indicates superior sunlight absorption from both the front and back sides, maximizing overall energy capture.

- Power generation efficiency is another area where HJT excels, boasting a 22.87% efficiency compared to TOPCon at 22.28% and PERC at 21.2%. This higher efficiency underscores HIM superior ability to convert sunlight into electricity, resulting in enhanced overall performance.

- HIT solar panels exhibit lower first-year power degradation at 1%, outperforming TOPCon at 1.5% and PERC at 2%. This suggests that HJT technology provides better initial stability in power output.

- Moreover, from the second year onward, HJT solar panels showcase an average annual power degradation of 0.35%, demonstrating superior long-term stability compared to TOPCon (0.4%) and PERC (0.45%).

- In terms of temperature coefficient, HJT solar panels stand out with a lower value of -0.243%pC, indicating reduced sensitivity to temperature variations compared to TOPCon (-0.32%/°C) and PERC (-0.35%/°C). This characteristic contributes to the consistent and reliable power generation of HIT solar panels across diverse environmental conditions.

In dusty areas with high humidity, which can create dew on the surface of solar modules, dust tends to adhere to the moisture. This is a common issue in Middle Eastern and African countries. In desert regions such as the Arabian Peninsula, flat PV panels must be cleaned twice a month and after every sandstorm. Even with low labor costs in these areas, the maintenance costs are substantial. Moreover, parking trucks on the street to clean the panels poses a safety risk and can cause traffic congestion. The best solutions for solar lighting systems in dusty and snowy areas include:

which can create dew on the surface of solar modules, dust tends to adhere to the moisture. This is a common issue in Middle Eastern and African countries. In desert regions such as the Arabian Peninsula, flat PV panels must be cleaned twice a month and after every sandstorm. Even with low labor costs in these areas, the maintenance costs are substantial. Moreover, parking trucks on the street to clean the panels poses a safety risk and can cause traffic congestion. The best solutions for solar lighting systems in dusty and snowy areas include:

- Using cylindrical solar panels.

- Applying self-cleaning nanocoating to the solar modules.

This coating prevents dust and bird droppings from sticking to the panels. With this coating, dirt can be easily removed after a light rain or by manually spraying water on the panels.

Sample of Traditional solar power tube with old technology

Considerations for Cylindrical Solar Panels:

Various companies manufacture cylindrical solar panels, and it is crucial to consider the following aspects:

- Material and Flexibility:

- Many manufacturers opt for non-flexible monocrystalline panels and force the solar cells into a cylindrical shape to cut costs. This process can lead to the development of micro-cracks in the cells, gradually diminishing the panel’s efficiency.

- Protection for these cells often involves the use of glass tubes, which are not only heavy but also

have low resistance to mechanical impacts like sandstorms. If these tubes crack, moisture can seep in, leading to cell corrosion.

- Efficiency vs. Flexibility:

- While CIGS (Copper Indium Gallium Selenide) cells offer excellent flexibility, their efficiency is relatively low, usually around 16%. This makes them less desirable for high-efficiency applications.

- Structural Considerations:

- Because glass tubes are heavy, stronger light poles are required to withstand wind resistance and ensure stability. This necessitates the use of more robust pole designs to maintain structural integrity under windy conditions.

- Additionally, the diameter of cylindrical panels with glass tubes is significantly larger, which can affect the overall design and wind load calculations of the light poles.

- Reflection and Safety Concerns:

- Cylindrical panels with glass tubes can reflect sunlight, making them unsuitable for use in many locations such as airports, where such reflections could pose safety hazards.

Recommended Solution:

For optimal performance and durability in cylindrical panels, flexible solar cells made from HJT (Heterojunction with Flexible cell technology) are highly recommended. These cells should be coated with UV-resistant and moisture-resistant layers to ensure long-term reliability and efficiency. By addressing these considerations, Lumentek produces cylindrical solar panels that offer both high efficiency and durability, suitable for a variety of challenging environments while minimizing safety and structural issues.

7- Sensor

Sensors are divided into microwave induction and infrared induction. Microwave induction can sense moving objects, and infrared induction can only detect temperature-bearing organisms.

Microwave Sensor

- Sensing distance 8-15m

- It affects both people and cars

Infrared sensor

- Sensing distance 5-8m

- Can only sense people

8- LED LIGHT SOURCE

The light source looks dazzling does not mean high illuminance. With the same lumens, if the lightemitting area of the LED light source is smaller, it looks more dazzling, and human eyes will mistakenly think that it is brighter. There is a vertigo index in the street light. The higher the vertigo index of the street light, the less safe when driving.

For the same lumens, the smaller the angle of the lens, the more concentrated the area hitting the ground and the brighter the light, but at the same time, the overage of the light is smaller.

We should not only look at the wattage of the LED light source but also the light effect. The brightness is the wattage multiplied by the light effect.

Attenuation rate of light after 5 years: 5%

Attenuation rate of light after 5 years:80%

9- CABLE

PVC cable with a copper conductor is not suitable for solar lighting systems, PV cable with XLPE sheath and insulation and Tinned copper conductor with UL and TUV certificate is the best type of cable for the solar lighting system.

10- CONNECTOR

Top quality manufacturers of connectors use nylon (PA66) and copper contacts with gold-plated which can use outdoors with the features of UV resistance and corrosion-resistant.

11- OPTICAL LENS

Polycarbonate lenses use in most solar lights Use high-temperature grade PMMA material with a 10-year no-yellowing guarantee with ZHAGA standards or PC lens with UV resistant material PC multi-lens with Self-adaptive glue technology, the efficiency approaches 95%.

12- PCB

13- CHARGE CONTROLLER

The charge controller is the brain of the solar lighting system.

It allows regulation and protection of the battery charge as well as the management of lighting and its programming.

The electronics parts of the Lumentek charge controller are completely encapsulated in an IP67 aluminum box providing it with tightness and perfect heat dissipation.

The MPPT charge controller also acts as a protection element for all components against:

- Overload

- Overcurrent

- Overtemperature

- Overvoltage

- Over-discharge

A boost constant current charge controller integrated with an LED driver combines two essential functions into one circuit. Let’s break down each part:

- Boost Constant Current Charge Controller:

This component manages the charging process of a battery or energy storage system. It takes the variable voltage from a power source (such as a solar panel or another power supply) and boosts it to a higher level while maintaining a constant current flow during the charging process. This ensures that the battery is charged efficiently and safely.

- LED Driver:

An LED driver regulates the current and voltage supplied to LEDs, ensuring they receive the appropriate electrical parameters for optimal performance and longevity. LED drivers are crucial for maintaining a consistent and stable current flow to the LEDs, preventing overcurrent or voltage spikes that could damage them.

- Integrated System:

When you integrate a boost constant current charge controller with an LED driver, you combine the functionalities of charging a battery and driving LEDs into one integrated circuit. This integration is commonly used in solar-powered LED lighting systems. During the day, the solar panel charges the battery through the boost constant current charge controller. Then, during the night or when needed, the LED driver uses the stored energy in the battery to power the LEDs, providing efficient and reliable illumination. This integrated approach is convenient and space-saving, making it a popular choice for solar-powered LED applications, especially in outdoor lighting and remote areas where a reliable power source is crucial.

- AC/DC hybrid charge controllers:

For areas experiencing extremely low sunlight radiation in winter or where the failure of solar lights poses irreparable risks, the utilization of AC/DC hybrid charge controllers is advised. These controllers, exclusively recommended by Lumintec, seamlessly switch the system to the grid electricity supply during low battery conditions and revert to battery power automatically once the batteries are fully charged.

14- THE BLACK LAMP HOUSING IS TOO HOT

The black lamps look high-end in the photos and indoors, but if they are installed outdoors, the background of the environment is a blue sky, white clouds, and green trees, and light-colored lamps are more coordinated with the environment.

Black is the most heat-absorbing. The temperature of the metal shell can reach up to 90 degrees Celsius under exposure, and high temperatures will damage the battery and LED light source.

Therefore, we recommend choosing high-pressure die-cast aluminum housing with Azco D1010 anticorrosion powder coating RAL 7035 matt, which will not absorb heat or fade when placed outdoors.

15- Automatic Wiper Cleaning is Not Practical

Automatic windshield wipers are not unique to solar street light factories.

This solution originates from a Chinese company in Shandong that manufactures solar power stations. Any solar street light manufacturer can purchase a ready-made solar windshield wiper solution from this company.

However, it is not practical to clean the wiper automatically because adding This function significantly increases the cost. If the motor breaks and the wiper stops on the solar panel, it will block sunlight absorption. Additionally, the wiper system cannot clean the solar panel effectively without water.

17- TAILOR-MADE SOLAR STREET LIGHT

While cost-conscious consumers often gravitate towards the cheapest options, affordability doesn’t always translate to cost-effectiveness. The durability and performance of the product are equally critical factors to consider. For example:

- A $300 high-quality solar light with a 10-year lifespan results in an average annual cost of $30.

- Conversely, a $100 poor-quality solar light lasting only one year entails an average annual cost of $100. Additionally, the wasted time and energy costs associated with frequent breakdowns render it an unwise investment.

16- Solar and Wind Energy Hybrid

Streetlights are a Gimmick Solar charging involves converting solar energy into electrical energy, which is then stepped down and converted to DC power to charge the battery. Wind energy charging converts mechanical energy into electrical energy, with the alternating current being stepped down to direct current to charge the battery. These two energy conversion Mechanisms and their respective conversion equipment are different.

Using wind energy to charge the battery of a solar street light can negatively impact the battery, causing it to decay quickly. Therefore, wind and solar energy should not be mixed. Currently, most solar and wind energy hybrid streetlights on the market rely solely on solar power, with the wind energy component disconnected from the battery.

In essence, the wind energy feature serves only as a decorative element

rather than a functional power source.

THERE ARE 4 TYPES OF SOLAR STREET LIGHTS:

Although all-in-one solar streetlights are not the most ideal option for tropical regions due to the compact design combining the solar panel and battery in a single enclosure, leading to direct heat transfer from the panel to the battery, they remain popular in various projects due to their affordability and straightforward installation process. However, the primary challenge with systems utilizing flat solar panels, especially in snowy and dusty areas, is the accumulation of dust or snow on the panel surface, hindering battery charging. This not only directly affects

the battery’s longevity but also results in considerable expenses for cleaning the panel surface, a task that must be carried out at least monthly.

Moreover, the limited battery capacity and panel dimensions of these all-in-one systems may not be sufficient to meet the energy demands in some applications. Additionally, it should be noted that in many inexpensive all-in-one solar streetlights, the tilt angle of the panel and the alignment of the LED module are fixed.

In numerous instances, when lights are installed on both sides of a street, it’s not always possible to adjust the solar panel angle to maximize solar absorption.

When we buy quality solar streetlights, we must not just look at the specifications advertised by the suppliers. Because the battery that the supplier may advertise is 100Ah, but the actual product purchased is only 10Ah. Even with the same capacity, the available capacity of batteries of different grades is different. For the same solar street light, some suppliers label 60W, and some may label 300W.

People want to buy the cheapest products, but the cheap ones do not mean the most cost-effective. It also depends on the effect and longevity. For example:

- With the 10 years lifespan of a $300 high-quality solar light, the average annual cost is $30.

- With the 1-year lifespan of a $100 poor-quality solar light, the average annual cost is $100. If it is broken, it is a waste of time and energy cost, which is actually not worth it.

- The charging and discharging environment temperature of the LiFePO4 lithium battery is up to 65 degrees Celsius.

- The charging and discharging environment temperature of the Ternary li-ion lithium battery is up to 50 degrees Celsius.

- The maximum temperature of solar panels in summer can reach 90 degrees Celsius.

Therefore, if you are in a hot area, such as :

- Africa: Algeria, South Africa, Angola, Morocco, Rwanda, Liberia, Ghana, Mauritius, Equatorial Guinea, Botswana, Gabon, Namibia, Tunisia, Cameroon, Nigeria

- Middle East: Saudi Arabia, Kuwait, UAE, Oman, Qatar

- Southeast Asia: Malaysia, Philippines

- South America: Chile Mexico

You can only use LiFePO4 lithium batteries. Ternary batteries are easy to catch fire. And the heat dissipation performance of the lamp must be good, and the solar panel should not be in direct contact with the battery.If you are at a latitude greater than 15 degrees, the sun will have an inclination angle greater than 15 degrees with the ground. Try to consider solar street lights with adjustable solar panel angles. Solar streetlights installed on both sides of the road should not have solar panels facing away from the situation of sunlight.

Every time the PN junction temperature of the LED chip increases by 10 degrees, the life span of the semiconductor device will decrease by multiples. It can be said that heat dissipation is an important guarantee for ensuring the life and quality of LED street lights. In this regard, bad manufacturers mainly use cutting corners to reduce costs, and this hazard cannot be found at the beginning of use, and it usually takes a period to find out.

The increase in temperature has an impact on the calendar life and cycle life of lithium batteries. The effect of temperature on the life of lithium batteries conforms to the Arrhenius equation. The temperature of lithium batteries increases, and the reaction speed increases. Related research shows that the temperature of lithium batteries per liter at a temperature of 10°C, the degradation rate doubles. When the remaining capacity is 90% of the same battery cell, the output capacity at 25°C is 300kWh, while the output capacity at 35°C is only 163kWh. When the temperature rises by 10°C, the cycle life of the battery cell is reduced by nearly 50%.

It can be seen that temperature has a significant influence on the cycle life of lithium batteries. Therefore, in the process of battery use, it is necessary to avoid long-term use of the battery under high-temperature conditions, especially the high-rate charge-discharge cycle of lithium batteries under high-temperature conditions, in which is also the main reason why the battery must be temperature controlled.

Therefore, the heat dissipation performance of the lamp must be considered. The solar panel is scorching when exposed to the sun. The solar panel must not be next to the battery and the LED light source.

The solar panel of the normal all-in-one/integrated solar street light is next to the battery, and it is a sealed space. The internal temperature can reach 70 degrees Celsius, which greatly damages the lifespan of the battery and the lamp beads. So, we recommend all-in-two or split-type solar street lights.

For using AIO-integrated solar street light in a high-temperature area, Lumentek has the following solutions:

- using thermal switch into charging system, when temp. is over 55 ℃, the switch will disconnect to cut off charging from the solar panel to the battery, and will re-connect automatically when the temperature is below 55℃.

- using heat insulation material to pack the battery pack, to guarantee inner temp. is less than the outside environment temperature in hot summer to protect the battery

- Using high-temperature battery cell.

Because the solar panel is mounted onto the lighting fixture, all-in-one systems are not very flexible when it comes to directional angles.

Lumentek uses a rotatable and adjustable led module in order to solve this problem

The actual capacity of the battery

Some parameter table Ah look very big, but we buy Wh instead of Ah.

Wh=Ah*V, we can’t just look at the capacity of Ah, but also the voltage. E.g:

- 90Ah, 3.2V actual battery capacity is 90Ah*3.2V=288Wh.

- 30Ah, 12.8V actual battery capacity is 30Ah*12.8V=384Wh

Available battery capacity

A deep charge and discharge will consume the battery's capacity, so to protect the battery, the battery power is generally not reduced to the minimum. Different quality batteries have different pre-stored power ratios, for example, Lead-acid batteries must reserve 50% of the power, so the depth of discharge is 50% of the actual capacity.

The ternary battery must have 30% of the power, so the depth of discharge is 70% of the actual capacity LiFePO4 Lithium battery only needs to reserve 1% of power, so the depth of discharge can reach 99% of the actual capacity.

It can be seen that, in order to achieve the same available capacity, the ternary li-ion battery configuration must be higher than that of the LiFePO4 lithium battery.

What is A grade or Class A battery cell?

The battery factory arranges production according to the production capacity and technical capacity of the factory. After a series of battery manufacturing processes, the final product is delivered to the customer; After mass production of battery cells with the same specifications, it is necessary to measure the cells' rated capacity and internal resistance through a series of testing procedures. If the rated capacity of the cell reaches A predetermined value, the internal resistance is lower than the specified value, and the appearance, performance, and other qualified cell is called Grade A cell.

What is a B grade or Class B battery cell?

Any factory producing products must have a defect rate. Then this defect rate determines the vitality of a factory. There will not be a big gap between the first-line lithium battery and the third-line lithium battery factory in the lithium industry, purely technology, ingredients, etc. Still, the gap between the defect rate is enormous; the first-tier manufacturers can achieve about 2%. In comparison, the second and third-tier manufacturers are likely to achieve 5-10%. It is precise because of this defect rate that grade B cell is created. The grade B battery in rated capacity, internal resistance, appearance, or performance, and the Grade A cell has a certain gap.

Class A LiFePO4 Lithium Battery

- 2000 charge and discharge cycles

- 10-15 years lifespan

- Good high-temperature stability

- Depth of discharge up to 99%

Class B LiFePO4 Lithium Battery

- 1200-1500 charge and discharge cycles

- 5-6 years lifespan

- Good high-temperature stability

- Depth of discharge up to 99%

Class C Ternary li-ion lithium battery

- 800 charge and discharge cycles

- 3-4 years lifespan

- Easy to catch fire at high temperature

- Depth of discharge up to 70%

Class D Disassemble lithium battery

- 300 charge and discharge cycles

- Less than one year lifespan

- Unstable

- Capacity decay Fast

Lumentek uses A-Class LiFePO4 lithium batteries.

The solar panel is not only depends on the size but also its conversion efficiency.

Generally, the conversion efficiency of polycrystalline silicon solar panels is 12%, and the conversion efficiency of monocrystalline silicon solar panels is 15%-24%. The manufacturing cost of monocrystalline solar panels is higher than that of polycrystalline solar panels.

- Conversion efficiency>21% Life span 25 years

- Decay rate after 10 years: 10%

- High-strength tempered glass, anti-freezing, anti-sandstorm

- Conversion efficiency > 16%-17% Lifespan of 15 years

- Decay rate after ten years: 80%

- Low-strength tempered glass

- In dusty areas with high humidity that can create dew on the surface of solar modules, dust can adhere to wetness. This is a general problem in the Middle East and African countries.

In desert regions, such as the Arabian Peninsula, flat PV panels must be cleaned 2 times per month as well as after a sand storm. Despite low labor costs in these regions, this causes significant maintenance costs. Moreover, parking trucks for cleaning on street are a safety risk and can cause congestion.

We have the following solutions for our solar street lighting system in dusty and snowy Areas:

- Using Cylindric solar panels

- Coating self-cleaning Nanocoating on the solar module, stops dust and bird poo from sticking to PV panels. With the help of the coating, all dirt will be easily removed after a little bit of rain or after manually spraying water on the panels.

The cylindrically shaped solar panels have the following advantages comparing flat photovoltaic panels:

- Reduce dirt deposits. Reduce maintenance costs.

- Reduce wind loads and pole costs.

- Pretty design.

Sensors are divided into microwave induction and infrared induction. Microwave induction can sense moving objects, and infrared induction can only detect temperature-bearing organisms.

Microwave Sensor

- Sensing distance 8-15m

- It affects both people and cars

Infrared sensor

- Sensing distance 5-8m

- Can only sense people

The light source looks dazzling does not mean high illuminance. With the same lumens, if the light-emitting area of the LED light source is smaller, it looks more dazzling, and human eyes will mistakenly think that it is brighter. There is a vertigo index in the street light. The higher the vertigo index of the street light, the less safe when driving.

For the same lumens, the smaller the angle of the lens, the more concentrated the area hitting the ground and the brighter the light, but at the same time, the overage of the light is smaller.

We should not only look at the wattage of the LED light source but also the light effect. The brightness is the wattage multiplied by the light effect.

210 lm/w LED chip

Attenuation rate of light after 5 years: 10%

110 lm/w LED chip

Attenuation rate of light after 5 years:80%

PVC cable with a copper conductor is not suitable for solar lighting systems, PV cable with XLPE sheath and insulation and Tinned copper conductor without UL and TUV certificate is the best type of cable for the solar lighting system.

Top quality manufacturers of connector use nylon (PA66) and copper contacts with gold-plated which can use outdoors with the features of UV resistance and corrosion-resistant.

Polycarbonate lenses use in most solar lights but the best optical lens is high-temperature grade PMMA material with a 10-year no-yellowing guarantee with ZHAGA standards.

The charge controller is the brain of the solar lighting system.

It allows regulation and protection of the battery charge as well as the management of lighting and its programming.

The electronics parts of the Lumentek charge controller are completely encapsulated in an IP67 aluminum box providing it with tightness and perfect heat dissipation.

The MPPT charge controller also acts as a protection element for all components against:

- Overload

- Overcurrent

- Overtemperature

- Overvoltage

- Over-discharge

The black lamps look high-end in the photos and indoors, but if they are installed outdoors, the background of the environment is a blue sky, white clouds, and green trees, and light-colored lamps are more coordinated with the environment.

Black is the most heat-absorbing. The temperature of the metal shell can reach up to 90 degrees Celsius under exposure, and high temperatures will damage the battery and LED light source.

Black shell temperature up to 82.2 degrees Celsius

The temperature of the silver casing is significantly lower

Therefore, we recommend choosing a silver shell as much as possible, which will not absorb heat or fade when placed outdoors.

Automatic windshield wipers are not unique to the solar street light factory. This solution comes from a company in Shandong that makes solar power stations. Any solar street light manufacturer can purchase a ready-made solar windshield wiper solution from this company.

It is not practical to clean the wiper automatically, because adding this function will significantly increase the cost. If the motor is broken and the wiper stops on the solar panel, the entire solar panel cannot absorb sunlight also wiper system cannot clean solar panel without water.

Solar pole lights, solar panels are attached to the poles, and the effect of sunlight is very limited, and the absorption effect of solar energy is only 1/5 of ordinary solar panels. When the sun is at its maximum, that is, when the sun is directly above, the absorption effect of the pole solar panel is almost zero.

Solar charging is the conversion of solar energy into electric energy, and the DC power is stepped down and converted to DC power to charge the battery. Wind energy charging converts mechanical energy into electrical energy, and the alternating current is stepped down to direct current to charge the battery.

The two energy conversion mechanisms are different, and the conversion equipment used is also different. If you use wind energy to charge the battery of the solar street light, it will impact the battery and cause the battery to decay quickly. Wind energy and solar energy should not be mixed. At present, the solar and wind energy hybrid street lights on the market generally only have solar works, and the battery is not connected to the wires of wind energy.

Wind energy is only an imaginary project as decoration.

With consideration of all the above-mentioned points for the production of a good quality solar light, a custom-made solar lighting system designed based on Geographical location and customer demands will demarcate Lumentek comparing other manufacturers.